Environmental challenges are pushing the manufacturing sector towards innovative sustainability solutions. Industries must adopt sustainable practices not just to minimize adverse environmental impacts but also to ensure their long-term success. Introducing IoT and sensors, known as “Sustainability 4.0,” is a significant step in reducing emissions and making manufacturing more sustainable.

Sustainable Manufacturing Practices

Manufacturing is one of the industries with the highest environmental impact, leading to significant carbon emissions, pollution, and resource depletion.

There’s, however, already a shift happening in the sector. Key players turn towards more sustainable green operations driven by new technologies, regulatory demands, and consumer expectations. According to recent research, 54% of businesses believe that emerging technologies have the potential to play a vital role in accelerating sustainability efforts.

Here is how tech advancements change the sector:

- Strategic Collaborations and Investments in Clean Technologies: Manufacturing companies proactively seek collaborations with clean energy firms to electrify their processes and minimize emissions. A significant step towards achieving this objective is the adoption of hydrogen fuel cell technology. For example, a leading engine manufacturer is investing over $1 billion to develop zero-emission solutions.

- Development of Specialized Verticals for Electrification: To streamline the transition to electrification, manufacturers are establishing specialized units dedicated to developing zero-emission technologies.

- Smart Factories and Industry 4.0 as Catalysts for Sustainable Manufacturing: Smart factory technologies, encompassing the Internet of Things (IIoT), Artificial Intelligence (AI), and Big Data Analytics, are driving a revolution in the manufacturing industry, collectively known as Industry 4.0. As of 2023, approximately 25% of manufacturing plants have integrated these technologies, making them “smart.”

- Digitalization and Data Analytics Driving Decarbonization Efforts: The use of the Industrial Internet of Things (IIoT) is expected to rise from 10% of manufacturing companies in 2020 to 50% by 2025. Additionally, a single assembly line is projected to produce up to 70 terabytes of data per day. This highlights the vital role of smart digitalization in improving sustainability efforts across industries.

Iot Solutions and Sensors Use Cases in Manufacturing

Integrating the Internet of Things (IoT) within the manufacturing sector transforms traditional production facilities into smart factories. IoT devices and sensors collect and analyze data in real-time, enabling manufacturers to optimize operations, reduce waste, and improve decision-making.

According to a study conducted by Deloitte, more than 70% of manufacturers have incorporated data analytics and cloud computing into their operations, with almost 50% using IoT sensors and devices. These technologies are crucial for the smart factory concept, as they improve operational efficiency and productivity in the following ways:

- Supply Chain Visibility: Real-time tracking of materials and products is now more streamlined with IoT devices. This clarity improves the efficiency of the manufacturing process and keeps things transparent across the supply chain.

- Energy Management: By keeping tabs on manufacturing facilities’ energy use, IoT technology identifies where companies can cut back on consumption. This saves costs and lessens the environmental footprint produced while creating manufactured products.

- Quality Control: Continuous monitoring of the production line through IoT sensors ensures that quality issues are caught early. This means products consistently meet high standards.

- Environmental and Emission Monitoring: Real-time data from IoT sensors help us quickly identify and act on emissions of pollutants, making it easier to minimize environmental impact in the production process.

Case Study: IoT in Action

Cognizant’s Industrial IoT Platform helped a global tool manufacturer improve its operations across 100+ factories. By implementing a cloud-based Industry 4.0 platform and fitting equipment with IoT sensors, Cognizant provided visibility into production metrics and monitored efficiency, productivity, and uptime. The implementation improved overall equipment effectiveness, accurate order fulfillment, lower error rates, reduced energy costs, and enhanced safety.

Advanced Techniques for Sustainability in Manufacturing: Aiot and ML

Integrating Artificial Intelligence (AI) and Machine Learning (ML) with the Internet of Things, known as AIoT, is crucial in advancing sustainable manufacturing. Using IoT sensors equipped with ML algorithms enables, for example, predictive maintenance.

Machines can be monitored in real-time, and failures can be accurately predicted before they occur. As a result, timely maintenance can be done, significantly reducing downtime and maintenance costs. Moreover, it also helps to conserve resources and minimize emissions by ensuring machinery operates at peak efficiency.

The use of AI and ML to optimize processes is becoming increasingly popular. These technologies use the vast amounts of data gathered by IoT sensors to improve efficiency and streamline manufacturing operations, making them more effective and environmentally friendly. By continuously learning and adapting, AI and ML systems can lower energy consumption, giving businesses a much-needed competitive advantage.

Case Study - AIoT and ML

The collaboration between Microsoft and Accenture on AI-driven solutions for methane emissions reduction in the energy sector is a prime example of how artificial intelligence is revolutionizing traditional industries, including manufacturing. Using AI to detect, quantify, and reduce methane emissions, the project demonstrates its potential to address complex industrial challenges, such as environmental monitoring and compliance. This approach can be paralleled in manufacturing, where AI technologies are increasingly deployed for predictive maintenance, quality control, and supply chain optimization.

Challenges to Implementing Sustainable Manufacturing Practices

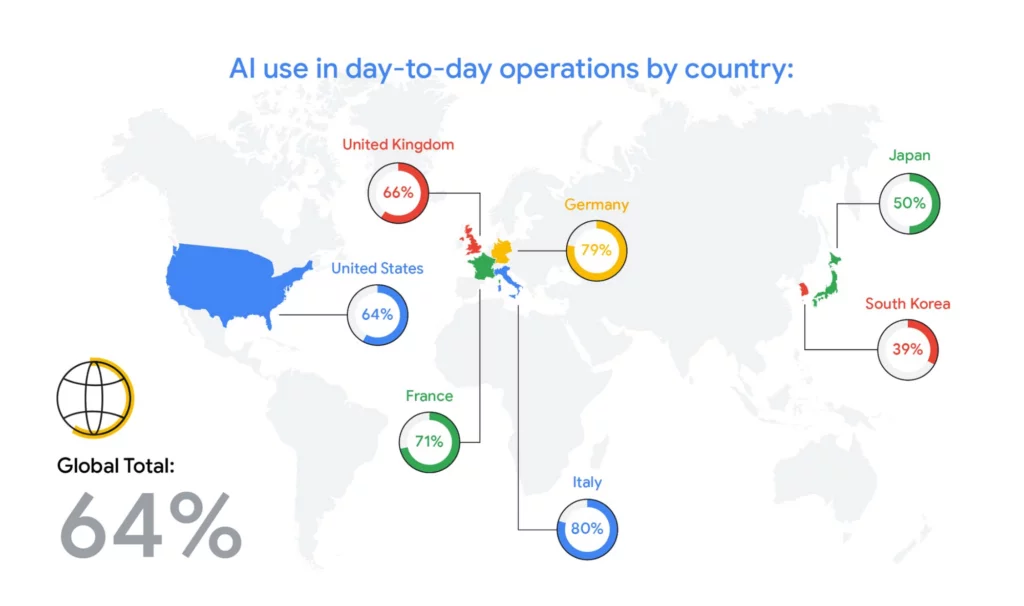

Implementing IoT and sensors in manufacturing faces several challenges that must be addressed for effective and ethical integration. They are the reason for the disparity in AI usage by geography, as illustrated below. The differences are mainly based on the availability of specialized platforms and tools for production-ready AI solutions.

Source: https://cloud.google.com/blog/products/ai-machine-learning/research-on-ai-trends-in-manufacturing

- Cost and Technology Integration: Integrating new IoT technologies with existing systems can be challenging due to high initial costs and complexity.

- Training and Skills: It is essential, albeit costly, to train employees to operate and maintain advanced technologies in a manufacturing environment effectively.

- Data Security and Privacy: Ensuring the security of sensitive data and compliance with privacy regulations is crucial to protect against cyber threats.

- Ethical and Environmental Concerns: Ethical issues regarding data privacy, responsible manufacturing, and the environmental impact of IoT devices need careful consideration.

- Compliance and Sustainability: Manufacturers must comply with regulations and implement recycling programs for IoT devices to achieve responsible manufacturing.

If you’re unsure how to address these challenges and define processes that minimize negative environmental impact, contact Scalo! Here is why it’s a good idea:

Achieve Your Sustainability Goal With Scalo

At Scalo, we understand the complexities of modern manufacturing, from the initial cost hurdle to ensuring seamless tech integration, skillful training, and robust data security.

We’re here to guide you through each step, helping you overcome these challenges with tailor-made solutions that boost efficiency, improve performance, and align with your commitment to sustainability practices. Our team specializes in creating software that’s not just smart but also responsible, ensuring your manufacturing processes are future-proof.

Ready to transform your manufacturing operations with IoT? Reach out to us at Scalo for expert guidance and software solutions that cater to the unique needs of your business. Let’s make sustainable manufacturing the standard together.